View count:

640

Facilities

Measurement Equipment Introduction

- Equipment Name: Surface Profiler

- Details: The instrument scans the sample surface with a (diamond stylus), detects the probe's vertical displacement, and converts it into an electronic signal to obtain data on film thickness and surface morphology.

- Equipment Name: Hall Measurement System

- Details: By applying a magnetic field and measuring the (Hall Voltage) generated in the sample, it can accurately determine key electrical parameters such as carrier type, carrier concentration, and carrier mobility. It is an indispensable measurement device in semiconductor material research.

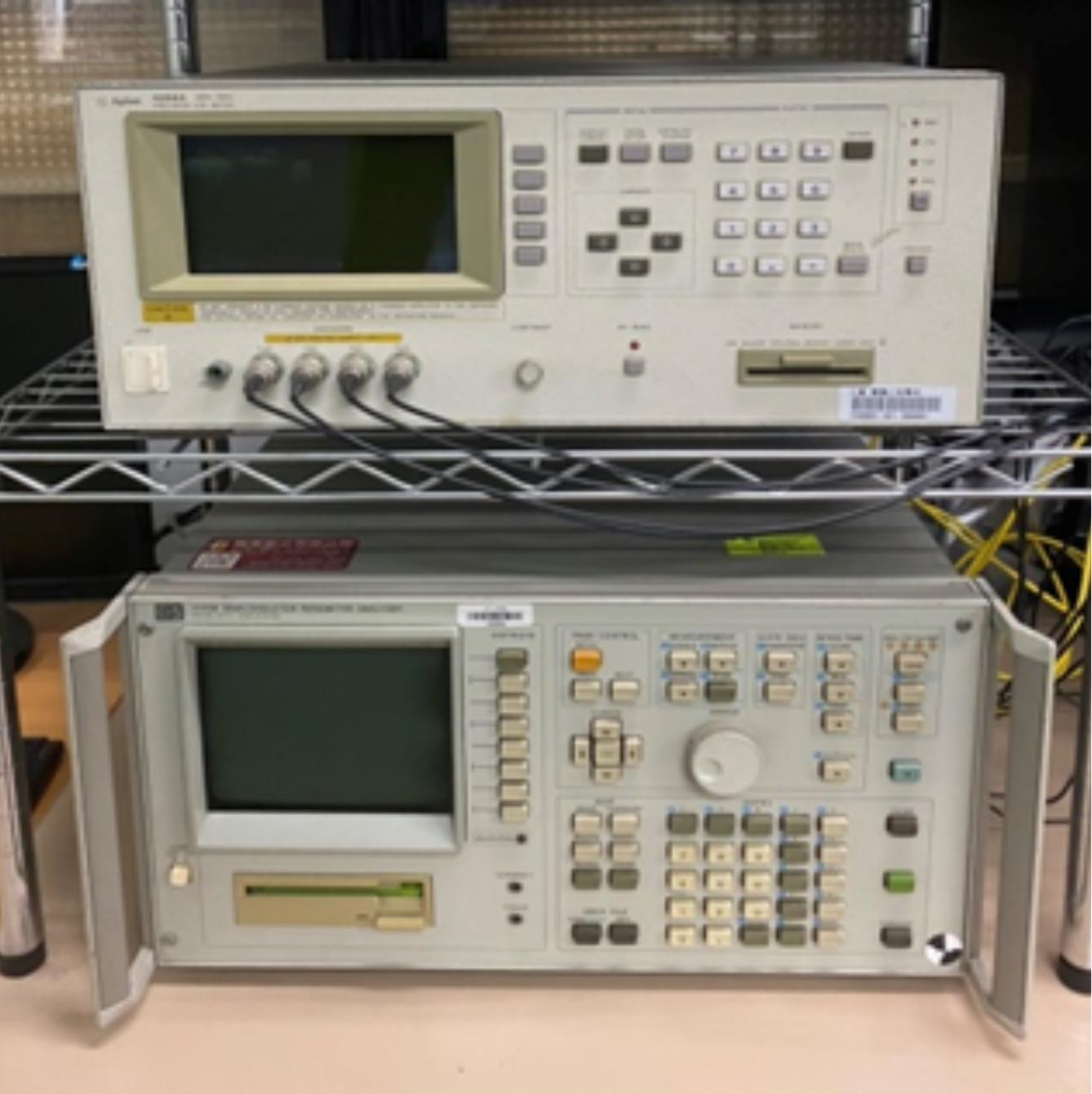

- Equipment Name: Semiconductor Parameter Analyzer

- Details: Capable of performing I–V (Current–Voltage) and C–V (Capacitance–Voltage) tests, assisting researchers in fully understanding component characteristics. Used in R&D, process verification, and quality control fields.

- Equipment Name: V101 Automated Testing and Integration System

- Details: The V101 Automated Testing and Integration System is a highly flexible testing platform suitable for semiconductor process verification, device analysis, and academic research.

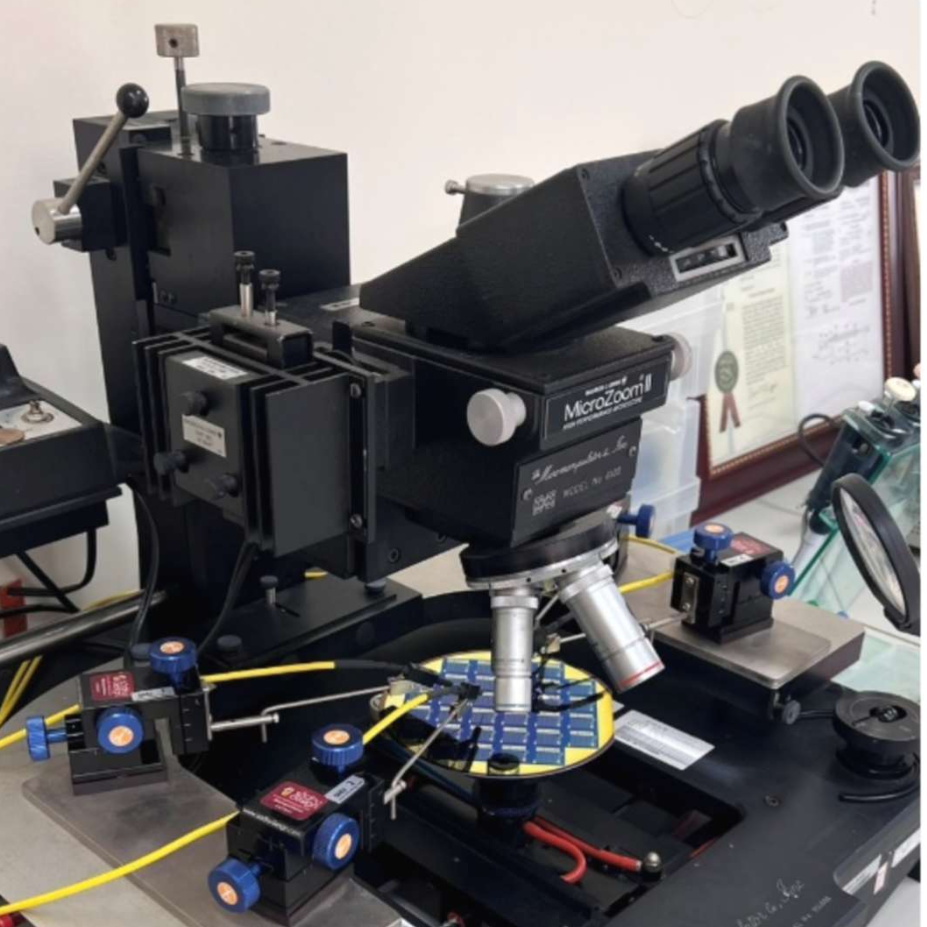

- Equipment Name: Probe Station

- Details: The Probe Station is a precision instrument equipped with a high-precision positioning stage and an optical microscope, used for electrical measurements at the wafer or chip level.

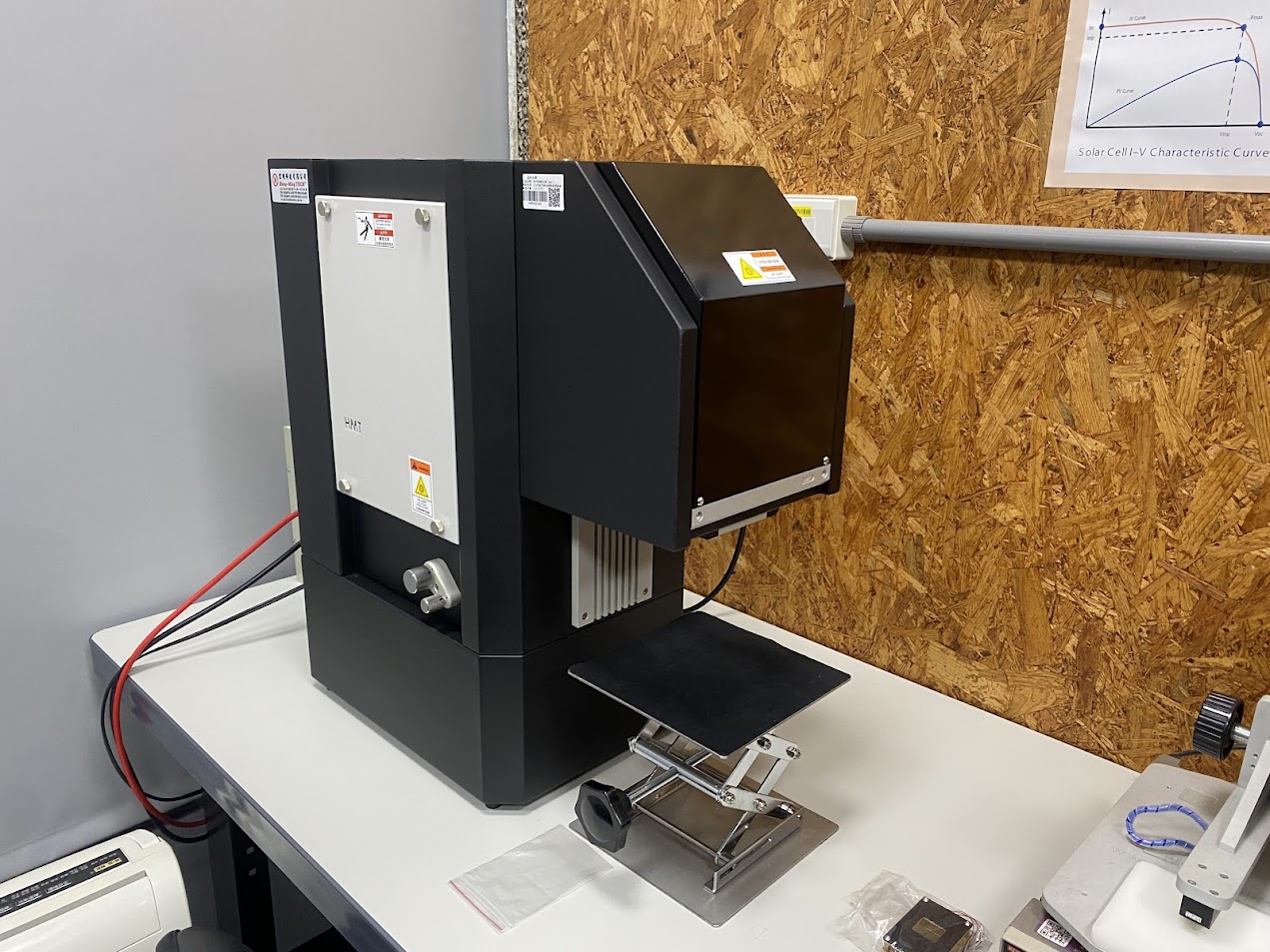

- Equipment Name: Solar Simulator

- Details: A Solar Simulator is a system that provides a standardized light source, designed to accurately simulate the natural solar spectrum (typically AM 1.5 Global). It is a key instrument for research, development, and performance evaluation of Photovoltaic Technologies.

- Equipment Name: Electrochemical Workstation

- Details: An Electrochemical Workstation is an integrated high-precision measurement system. Its core functions include a Potentiostat / Galvanostat and Electrochemical Impedance Spectroscopy (EIS).

Process Equipment Introduction

- Equipment Name: Evaporation Deposition System

- Details: Evaporation is a Physical Vapor Deposition (PVD) technique that uses high temperatures to evaporate materials into gas, which then deposits onto a substrate surface in a vacuum environment to form a thin film. This technology offers advantages like high purity, low contamination, and a simple process, and is commonly used for metal electrodes, optical coatings, and semiconductor processes.

- Equipment Name: Thermal Annealing System

- Details: Thermal annealing is a semiconductor heat treatment technique that uses heating to cause atoms within the wafer to rearrange, repairing defects, relieving stress, and improving crystal structure. Based on the heating method and duration, it is mainly divided into 'Furnace Annealing' and 'Rapid Thermal Annealing (RTA)'.

- Equipment Name: Sputtering System

- Details: Sputtering is a Physical Vapor Deposition (PVD) technique that uses argon ions to bombard a target material, causing target atoms to be ejected by kinetic energy and deposit onto a substrate surface to form a thin film. This technology can produce high-density, high-adhesion films at lower temperatures and is commonly used in semiconductor, optoelectronic, and magnetic device processes.